| Please tell us your name and a brief description of what you do at SoleTech/Etnies? |

| Jason Smith, etnies product manager. I oversee the merchandising and development of the shoe line. I work with the designers on the design briefs and mange all the colors/material stories for each season. I also work with the designers and the team riders to help develop their shoes. |

|

| How did you end up where you are, and what did you study in order to get into footwear design? |

| As for me I donít do much of the designing, I leave that up to Dennys for the most part. I just give good input on detailing etcÖafter the shoe is designed. Iíve been at Sole Tech for almost 12 years, I worked in a skate shop that sold etnies and met the owner and rest is history. Iíve done everything from shipping, sales, marketing and to where I am now. |

|

| As far as the design process goes for sneakers, how do you start each one, or does it vary?

|

| We work with the marketing dept who gives us a design brief. From there the designers (with direction from me the PM) run with the design process and start sketching out ideas. |

|

| Whats the difference/benefit between a full rubber midsole versus a midsole that has the foam exposed? |

| I would say itís more of a design element more than anything. But weight definitely is reduced by having the ďdouble cupĒ as we call it. |

|

| You do a lot of design work on your site, what's your design background? |

| I just like to look at things. Its something that naturally progressed during the years. I worked at some Marketing and Advertising companies but it never felt "right". I am just not into designing a medicine package - and that was what they wanted me to do. I want to do my own stuff and use my energy for something that i can relate to. |

|

| Fill us in on terms such as 400 NBS, EVA and what they mean? |

NBS is the density and abrasion resistance rating given to rubber. 400 nbs is the highest grade of rubber that still allows a shoe to be flexible and avoid cracking.

EVA stands for Ethylene-vinyl acetate itís viscous and elastic foam built into the shoe and serves to absorb the impact forces (basically the padding between your feet and the pedals or ground) Weíve started to also add System G2 in place of EVA in key points to protect the foot even better. |

|

| Regarding the BMX team rider shoes (roscoe, terranea, rooftops), how do those come to be? Does Etnies approach the rider, or vise versa? |

| We work with the team managers and decide which riders we plan to release pro models for and then basically get them in the office and sit down and talk about what they like, what they want out of their shoe and also what they want it to look like, of course |

|

| Does the rider usually know what they want their shoe to look like, or do they tweak existing designs? Or do you guys start from scratch? |

| It goes both ways, it really depends on the rider. |

|

| Have you asked everyone to help, or do people just volunteer? |

| Some ask to contribute, some get asked by me. Its almost 50 / 50. I like it if people send stuff. myspace helps - hahaha! |

|

| Do you sort of have to give the riders a crash course in design and materials, or do you just offer up your knowledge from the get-go? |

| Yeah we break it down for them for sure, but we pretty much just jump in and they can ask questions anywhere along the way. |

|

| What are some things the riders ask for in their shoes? (breath ability, comfort, stiff etc...) |

| When designing BMX shoes, obviously the bottom tread is one of the most important details; we need to design a bottom that is compatible with pretty much any type of pedal. Itís completely different than when we design a skate shoe tread. In some cases a skate tread works for BMX for example Rubenís outsole which came from the Mike Vallely shoe. |

|

| Have there been any requests/ideas from the riders for their shoes that didnít work or wouldnít fly? |

| Yes, sometimes design element that would be functional but just would make the shoe look weird, itís really a fine balance between the function of a shoe and the styling |

|

| In regards to the colorways, does the rider have free reign? |

| Yes and No. We definitely need to make shoes that your everyday Joe buying the shoes would pay his hard earned money for but we do let the riders have fun and pick random colors, thereís always a point where we have to say no. Mike Escamilla is notorious for doing crazy colors that we all knew heíd only wear. Things like that build hype for the shoe in general though so itís good to do. |

|

| What steps do you take to adapt each specific signature shoe to its riderís foot, so they are truly happy with the feel? |

| We use various types of lasts (mold/shape that the shoe is built around) that fit different types of feet. Also padding, thicknesses and overall heights come into play during the design process. |

|

| Which signature model was the most difficult to complete and why? |

| I would say Rubenís shoe. It wasnít anything to do with Ruben himself but while we were developing his shoe he was on like an 18 month world tour that never seemed to end. SO to catch up with him to talk shoes or to ship him new samples extended the process quite a bit. But the finished product speaks for itself, well worth the wait! |

|

| Are there any aspects of sneaker construction that are a must for a BMX shoe? |

| Well completely different from skate shoes are the wear points in which the shoe breaks down. So we need to take into consideration the inside of the shoes more that we do in skate for sure because the shoes are constantly rubbing on the cranks, and frame etcÖ As I mentioned before, the tread pattern is very important for pedal grip. Overall flex is a factor as well. |

|

| Any new rider shoes in the works that you can tell us about? |

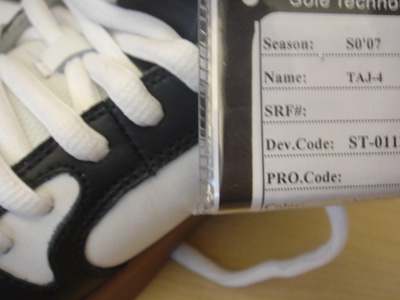

| Well, we are working on an update to Tajís shoe right now and any other projects youíll just have to wait it out a bit, watch the blogs for sneak peeks!! |

|

| Between designing and samples, How long does it take to bring the final product to life? |

| From a piece of paper to the shoe wall at the shop between 10-18 months. |

|

| Fill us in on System G2, STI foam and how it benefits the wearer? |

| I would say the best thing to do is experience them for yourself by buying a pair of etnies or checking the STI website www.stilab.com for more info. |

|

| What can you tell us about sneaker development that someone might not know? |

| We donít use child labor to make the shoes!!!! |

|

| Do you guys have any favorite sneakers or brands outside of your industry? |

| Nike, New Balance. |

|

| At the end of the day, what is the most gratifying thing about your job? |

| Seeing a shoe that you worked on someoneís feet out in the street/. (and working with Dennys) |

|